Radix Implant System Hexagon

Benefit from the latest in dental implant research and practice: We combine the best of the world‘s leading implant systems. You will receive excellent quality with easy handling at exceptionally attractive prices.

The radix Hexagon Implant System covers a wide range of applications and allows you to make high-quality implants accessible to a larger clientele of patients.

Selection and application are optimally matched to the requirements in dental practice.

Radix stands for transparency, good advice and quality Made in Germany.

The advantages of the radix Implant System Hexagon at a glance:

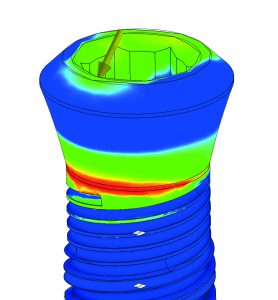

• Perfect primary and secondary stability

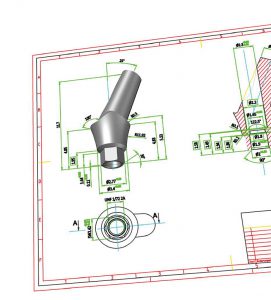

• Hexagon socket for safe and flexible positioning of the abutments in the implant

• Stable screw-cone connection for even load distribution and anti-rotation safety

• Self-tapping screw implant with compression thread and micro thread in the upper region for optimal

protection of the crestal jawbone

• Initial high bone-to-implant contact for rapid osseointegration due to special surface treatment

• Ideal restorative flexibility and long-term mechanical stability

• Also suitable for single-stage surgical procedures

Made in Germany

We develop and manufacture our implants from first-class materials exclusively in Germany in order to meet the highest quality standards. Our value creation chain combines innovative design with state-of-the-art testing and

manufacturing processes.

Designation

Designation

Designation

Bone Level Implant

Implant without supracrestal elements and which is completely sunk into bone level.For one- and two-stage implant placement. If hard and/or soft tissue have to be augmented. Preferred in the anterior and premolar region – e.g. with a high smile line and thin gingiva. Usability in complex aesthetic cases is well predictable.

Tissue Level Implant

With implant shoulder that extends a few millimetres above bone level and contributes directly to soft tissue formation. Also suitable for single-stage implant placement. Especially in the posterior region to bridge large vertical and horizontal dimensions. Well suited for hybrid prosthetics.

Surfaces

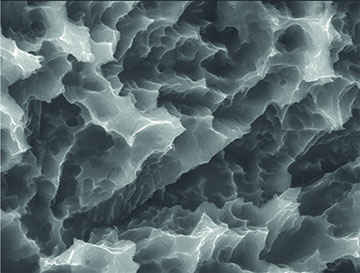

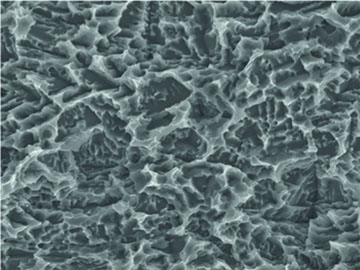

Grade 4 Titanium Surfaces

The radix implants are first gently conditioned with zirconium oxide particles. Then they are structured through acid treatment. The implants are treated according to validated processes.

Grade 4 titanium is an inert biocompatible material that is roughened on the surface to support osseointegration

of the implant.

Advantages at a Glance:

• Homogeneous surface structure

• Determined roughness: 1.5 mµ +/- 0.5 mµ

• Clean by Design: no corundum impacts on the surface

• Dimensional stability of titanium components through shot blasting

• No residues from blasting agents

Radix Instrument Set

• The result of decades of experience and development – Made in Germany

• Optimum cutting performance | low vibration | excellent durability | outstanding precision

• Validated cleaning in accordance with DIN EN ISO 17664

• Depth markings: 6/8/10/11.5/13/16 mm

• Drill depth stop with 4 lengths

Radix Storage Box

• The portable storage box – handy, clearly arranged

• Secure instrument fixation

• Clear user guidance during the surgical procedure

• Easy cleaning, disinfection and sterilisation according to MDD

• For all steam sterilisation processes under vacuum (121 °C and 134 °C)

• For low temperature sterilisation with gas, H2O2 and H2O2 plasma

Bone Level

Tissue Level

--------------------------------------

Call Us

Phone: +90 212 525 02 08

Whatsapp: +90 555 077 20 19

--------------------------------------

Address

Kayabaşı Mah. Adnan Menderes Blv. Park Mavera 2 Sitesi T3 Apt. No: 2CA Başakşehir - İstanbul / TÜRKİYE

--------------------------------------

info@akcmedikal.com.tr

--------------------------------------

Working Hours

Mon - Friday: 09:00 - 18:00

Saturday: 09:00 - 13:00

Sunday: Holiday

AKC Medikal © 2019 All Rights Reserved